Business optimization is defined as “the process of identifying and implementing new methods that make the business more efficient and cost-effective.”

Sounds simple, right?

Wrong. The reality, as business owners and C-suite executives know, is that gaining the highest return for the lowest cost on all company expenses isn’t easy. While improving the bottom line by reducing rent is good, gaining similar savings by improving existing processes is better — much better. That’s because the more efficient process will pay back more and more as volume increases. And it can become a catalyst for reducing the operating cost of other related processes.

Experienced interim executives understand that business process optimization is the Holy Grail of cost reduction and business efficiency. They are action-oriented leaders who begin looking for ways to create value and deliver real results to the clients from Day One. They know how to find hidden value in existing products, processes, and systems, how to implement actionable strategies, and how to gain the alignment necessary to optimize the business.

Assessing Operational Effectiveness

This requires assessing, understanding, and improving these key parts of the organization:

Profits

Great companies deliver above-average returns on investment, capital, and resources. These metrics allow shareholders, investors, and potential employees to compare companies for purposes of future engagement.

Interim executives look to improve profits by examining major indicators of cost, such as:

- Below-average revenue per employee, which could be an opportunity for price increases, a change in customers targeted, or performance issues of the sales team.

- High cost of goods, which entails examining the global supply chain’s shipping costs, storage costs, value-added services, rework, quality assurance, final packaging, and labor to produce.

- Profit margins by product or service line to ensure that each provides a meaningful return to the organization.

- Debt burden and interest expense as a percentage of revenue to find ways to pay off the debt faster.

- Fixed costs, which tend to be one-time endeavors, such as saving $10,000 a month in rent by consolidating facilities, but still can improve the bottom line and cash flow each month.

- Labor costs matched to function, which will help identify areas of the organization where administrative or other “non-value-add” functions may have become oversized.

- Product mix, to ensure higher margin products are always in stock and pushed by the sales team and low margin products are eliminated.

- Product return rates, which provide obvious clues to underlying inefficiency and customer satisfaction worries.

Process Efficiency

Continuous improvement is a hallmark of excellent companies. Each new level of performance for current processes serves as the baseline for another new process goal. It requires diving deep into all business operations to identify opportunities for process improvements.

The growing use of Lean techniques and Six Sigma to reduce waste in manufacturing is well understood, but implemented with varying degrees of success due to the complex global supply chains companies use to create their products. It is quite common for Interim COOs or CMOs (Chief Manufacturing Officers) to lead ground-up evaluations of corporate supply and value chain processes to see if all the benefits have been attained and whether the staff or other resources can be redirected for more improvement.

Non-manufacturing processes must be assessed as well to ensure bottom-line optimization. Tools such as Kaizen and workflow analyses can be used for administrative processes as well.

Throughout, it is critical to create a culture that is willing to embrace change as the new norm. To be effective, the whole organization must understand that the status quo will no longer be acceptable. The company must grow or it will be left behind by the competition.

Systems Improvement

Systems and technology are important parts of virtually every business process these days. Inefficiencies and inadequate or improperly utilized technology present opportunities for optimal solutions.

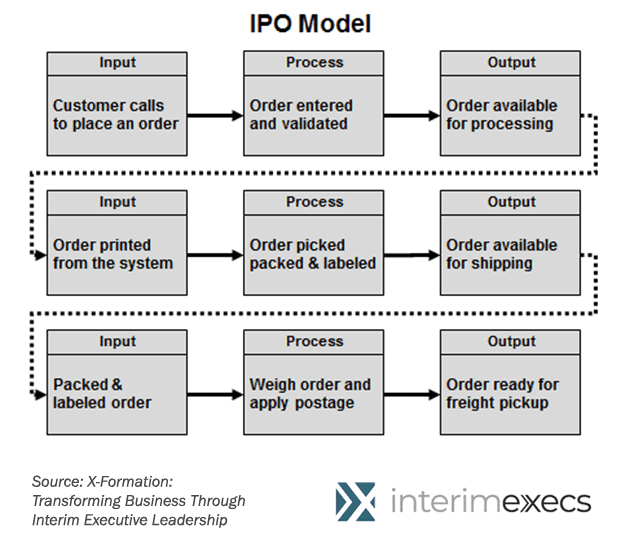

Assessing systems and process automation is critical to optimization strategies focused on closing critical gaps in technology. Oftentimes, interims will introduce new tools to the organization, such as formal process decomposition as outlined below using an Input/Process/Output breakdown.

People

Optimization techniques around people include looking at the comparative cost of employees, contractors, and partners.

Companies with urgent profitability or cash flow problems may need to consider pay cuts for team members or even staff reductions. Examining the cost of benefits and other employee-related expenses also should be part of the decision-making.

In some cases, contractors can be the way to meet business goals that require special expertise, especially for short-term challenges. Contractors are an on-demand workforce, so throttling their activities up and down to match real-time cycles creates a powerful and scalable business model.

Partners, such as interim executives, need to be measured by the value they create as compared to the cost of their services.

Raw Materials

Efficient business process management requires understanding the complete cost of the products. For example, many companies know the cost of raw materials or parts, but become unclear on transportation, storage, damage, and other related costs that should be captured and attributed directly to the product and not “overhead.”

Once the true costs of a product are understood, the gross margin at every price tier and volume can be analyzed to ensure the model can scale. Healthy KPIs at the distribution, wholesale, and retail levels are critical in driving customer enthusiasm for the product.

Fixed Expense & Overhead

Interim executives examine fixed costs in innovative ways by measuring the return on investment the fixed costs provide as compared to the business they support.

For example, store rent, utilities, common area maintenance, insurance, and the like set the baseline for the minimum performance of a retail location, and warehousing space can be measured by looking at the monthly cost to store each item based on inventory turns and revenue potential.

Viewing these costs as a component of overall performance can lead organizations to clearly see barriers to driving higher performance.

Discretionary Expenses

Not only are interim executives less attached to discretionary expenses, but they also tend to be more inclined to tie benefits to performance and goals. This approach creates awareness of these costs and the energy needed to accomplish goals.

It also has the interesting effect of driving employee innovation to look for redundancies and seek better uses of the money to drive higher perceived value to the organization.

Executing the Business Optimization Plan

Clients used to the “shoot, ready, aim” approach of operating where they start executing before a complete plan with clear goals is in place are often surprised by how smoothly a properly planned execution can be.

Thanks to their real-world experience leading large-scale transformation, interim executives balance the need for speed with that for quality thinking. They demonstrate the benefits of a methodical approach by bringing facts and data to drive transformation prioritization and plans.

Executive teams that are trying to improve performance often take a “go big or go home” attitude, figuring that major transformation needs to happen in big, bold strokes. While this is sometimes true, experienced interim executives know that there are usually opportunities for smaller innovations that can drive dramatically improved performance.

Once the executive team is clear on the plan and in agreement, communicating the plan to the organization along with anticipated impacts is crucial. In communicating the plan, the executive team shows confidence and clarity in addressing opportunities for improvement and provides the basis for employee feedback, ultimately winning the hearts and minds of the staff.

Contact InterimExecs to learn more about how InterimExecs RED Team – an elite group of CEOs, CFOs, CIOs, and COOs – can help your company assess operational effectiveness and implement a business optimization plan.

———————————

This article draws on the chapter “The Interim Executive Approach” featured in X-Formation: Transforming Business Through Interim Executive Leadership, a guide to interim management written by several veteran executives on InterimExecs RED Team.

The needs of a typical organization can be broken down into four major areas, each representing an execution discipline interims practice to assess needs and take action. See the other three parts of the series: Maximize, Strategize, and Organize